Chemical composition

| Al | Si | Mn | Cu | Mg | Zn | Cr | Fe | Ti |

|---|---|---|---|---|---|---|---|---|

| Remaining |

0.40 -0.80 |

0.15 | 0.15-0.40 | 0.8-1.2 | 0.25 | 0.04-0.35 | 0.70 | 0.15 |

Physical properties

| Tensile strength | Yield strength | Brinell hardness(HB) | Elongation |

|---|---|---|---|

| ≥180MPa | ≥110MPa | 95-100 | ≥14% |

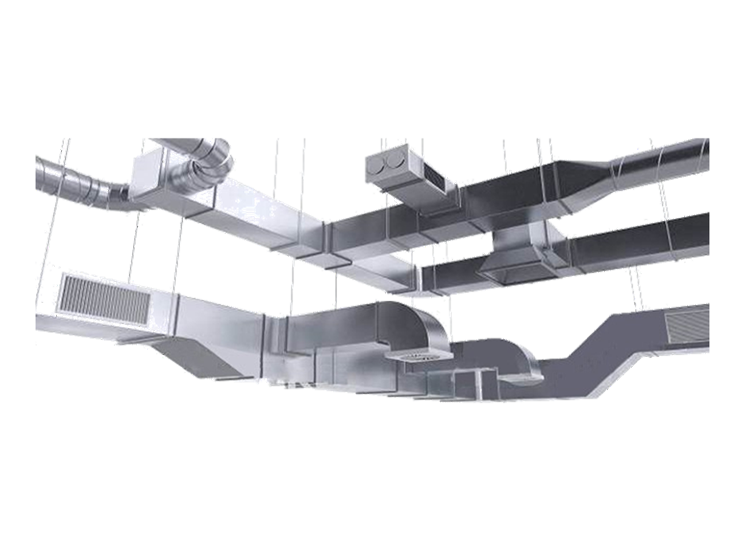

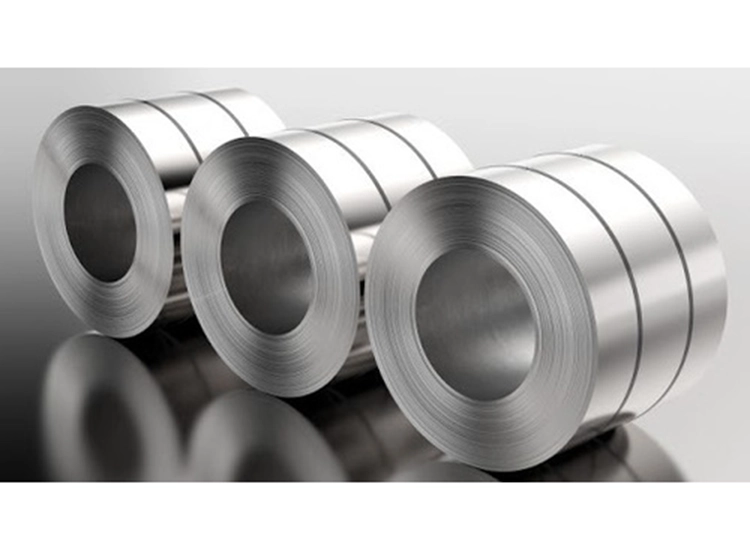

Aluminum coil is a metal product made by casting and rolling machine after calendering, bending and shearing. Widely used in electronics, packaging, construction, machinery and other aspects. According to the different metal elements contained in aluminum coils, aluminum coils can be roughly divided into 9 categories :1000, 2000, 3000, 4000, 5000, 6000, 7000, 8000, 9000 series.

Wide application: aluminum coil is widely used in electronics, packaging, construction, machinery and other aspects

| Product | Aluminum Coil |

|---|---|

| Property | Anti- Corrosion, Heat Resistant |

| Surface | Mill, Bright, Polished, Hairline, Embossed, etching |

| Production Process | Cold Rolled, Hot Rolled |

| Grade |

1000 Series: 1050, 1060, 1070, 1100, 1200, 1235, etc. 5000 Series: 5005, 5052, 5083, 5086, 5154, 5182, 5251, 5454, 5754, 5A06, etc. |

| Temper | H14, H24, H32, H112 ;T4, T651 Etc |

| Thickness | 0.02mm – 350mm |

| Width | 10mm – 2500mm |

| MOQ | 5 tons (According to specifications) |

| Payment Term | 30% TT for deposit,70% TT at sight balance before shipment |

| Package | Export wooden pallets, Craft paper, Anti-Blushing Agent. |

| Delivery Time |

Future goods: 20-30 Work days Ready Stock: 7-10 days. |