SASCO INDUSTRIES LLC is one of the leading manufacturers of HVAC ducts and duct accessories in Middle-East. Since its inception in 1977 in the Kingdom of Saudi Arabia, SASCO has expanded rapidly and today it has branches in UAE, Bahrain and Egypt with headquarters located in Abu Dhabi, UAE from 1994.

SASCO is involved in producing and distributing HVAC products for 30 years and it has been associated with some of the prestigious projects and leading MEP contractors in the region throughout this period. SASCO has completed projects in Saudi Arabia and U.A.E excess of AED 350 million and numerous landmarks stand testimony to the firm’s engineering capabilities. SASCO has also made considerable Exports in Foreign Markets, mostly to Bahrain, Qatar, Saudi Arabia and Oman.

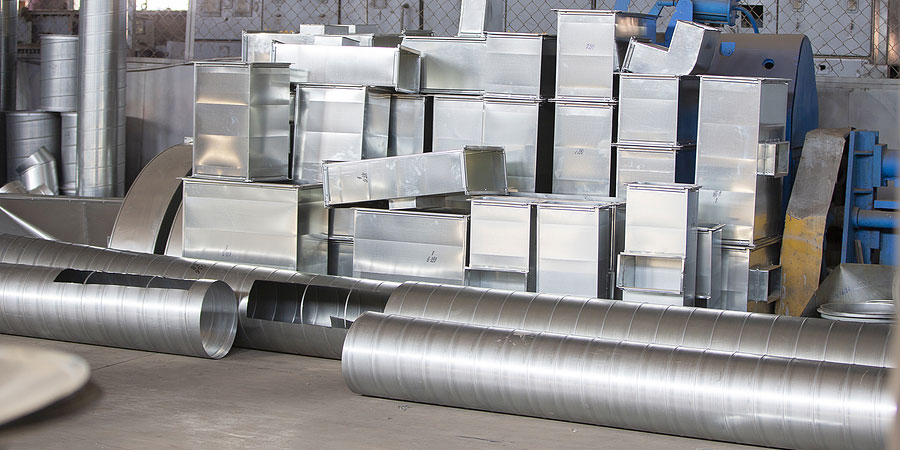

SASCO has maintained a policy of continuous investment in new products, technology, manufacturing expertise and ongoing training. The UAE plant is located in ICAD III with over 19,000 square meter production floor area equipped with state-of- the- art CNC machinery and skilled workforce enable SASCO to make its products with the shortest lead time and the highest quality. Owing to the large capacity of the plant and astute management skills.

SASCO is able to offer one of the most reliable and efficient HVAC products manufacture services in Abu Dhabi. SASCO produces 2,500 square meter Duct on Daily basis makes it one of the largest producers of Pre-fabricated GI Duct in UAE.

SASCO offers all types of High-Quality Ductwork to all international Ductwork Standards. The other product ranges include Sound Attenuators, UAE Civil Defense Approved Fire Rated Ductwork and other associated technical products like Flange Systems, VCD’s, Access Doors and Louvers.

The products manufactured are tested according to ASHRAE Standards. Duct construction as per DW144 /ASHRAE / SMACNA standards provides superior strength, low leakage rate and vibration free products. Awareness of customer requirements in this field has led SASCO to adapt their products to suit even the most demanding needs.

SASCO has been implemented Quality Management System to meet the specified requirements of Quality System ISO 9001. Manufacturing and assembly are carried out under strict controls and procedures in accordance with Quality Assurance System ISO 9001:2015.

SASCO has a strong management team with an aggregate experience of over 60 years in Air- conditioning Ductwork industry. Projects are completed on time and on budget. With SASCO extensive resources and knowledge gained from working in all sectors of the industry, they are able to tailor a project team to meet every client requirement. SASCO also have a highly skilled workforce ensure strength and reliability.

Ethos

Key Strengths

An extensive Coil Stock of galvanized iron coil of Lock forming quality of more than 1000 Ton will make up to 100,000 square meters of GI Ducts. We keep stock of all coils from the most trusted brand such as Nippon-Japan, Jindal-India, AGIS-UAE. Also, pre-insulated; black steel and stainless-steel ducts are supplied.

SASCO’s Production capacity is between 20000 ft²-25000 ft² (8 Hours Shift) in HVAC ducts.

Some of the key distinctive characteristics of SASCO which makes it the industry leader are, superior quality of product, reliability of services, shortest lead time, economical price, Perfect in finished dimension. Large capacity, wide range of size & thickness, Large technical expertise, focused customer needs, Special identification sticker for easy identification and installation, no limitation on duct size, Skilled workmanship in making tailor made ducts to address the demand, intensive quality and safety assurance program and the prominent name SASCO as the industrial leader in HVAC duct and duct accessories.

SASCO’s commitment to service and customer care underpins their efforts at every stage. From the inception of a project, their Business Development Managers, backed up by their fully computerized estimating department, provide prompt and accurate handling of pre- contract enquiries, quotations and budgets. With their extensive experience they pride selves on flexibility and problem-solving skills enabling them to offer value from the start.

From start to completion, every project undertaken by SASCO is closely monitored to ensure its smooth progress. From Electromechanical projects, HVAC products, ductwork manufacture and installation contracts to the custom manufacture of individual specialized items, uppermost in our priorities are the total satisfaction of their customers.

Certified to OHSAS 18001:2007 family of Health & Safety Standards, ISO 14001:2015 Environmental Management System and ISO 9001-2015 Family of Standards our commitment to quality never wavers. SASCO continuously drive for improvement, actively participating in the Construction Best Practice Program. We believe that by working in partnership with our clients and suppliers we can achieve the vision of an efficient, innovative and cost-effective industry. Closely monitoring our customer and project requirements from start to finish also enables us to benchmark our performance using industry standard Key Performance Indicators. The bench marking process allows us to keep abreast with the industries voice and meeting the demand on time without zero discrepancy